Why Choose Propane For Construction

Convenient:

Propane maintains its integrity over time and in extreme conditions. You can store it in tanks without worry of fuel degradation or contamination. Propane is always ready to work. Even in the coldest weather, it performs the way you need it to.Rugged:

The compact nature of propane makes it easy and safe to transport and store. In any terrain, we can deliver without the need for costly infrastructure.Lower Emissions:

Propane is a clean-burning fuel that can reduce your overall carbon emissions. Propane emits 60% less carbon monoxide than gasoline, 98% less particulate matter than diesel and contains virtually no acid rain-producing sulphur.How Does Propane Stack Up to Diesel?

|

|

PROPANE |

DIESEL |

||

|---|---|---|---|---|

|

Cost |

Propane costs up to 40% less than diesel. |

Historically, diesel is 40-50% more expensive and transportation costs to remote sites can be much higher than propane |

||

|

Emissions |

Propane minimizes environmental impact with as much as 15% fewer emissions and 98% less particulate matter than diesel. |

Diesel contains higher levels of Greenhouse Gas Emissions (GHGs) particulate matter and sulphur. |

||

|

Environmental Risks |

Propane vaporizes when released, eliminating the risk of contaminating water, ground or air. |

Diesel risks include costly environmentally damaging spills and fuel contamination from long-term storage. |

||

|

Lower Maintenance Costs |

Propane burns cleaner to reduce wear and tear on equipment, which results in less service and lower maintenance costs. |

Diesel is not as clean burning as propane. That means machinery could require more frequent maintenance, resulting in higher costs. |

Propane Applications for Construction

Propane’s versatility is one of its greatest strengths. From building heat to concrete curing, propane keeps your project moving.

Building Heat

Concrete Curing

Temporary Power

Propane Tools

- Propane Torch Wagons

- Propane Torches

- Hot Tar Kettles

- Roof Dryers

- Concrete Floor Saws

- Propane Construction Heaters

- Ground Thawing Equipment

- Air Compressors

SUPERIOR CONSTRUCTION SOLUTIONS

From a preliminary site assessment to delivery and maintenance, we take care of everything for home builders, construction companies and commercial developers.

FREE NEEDS ANALYSIS & ESTIMATE

Our technical experts come to your job site to determine your exact needs. We consider everything for your project such as BTU requirements, the number and type of heaters required, and design requirements. We will specify and install the right propane cylinders or tanks, vapourizers, regulators and valves.EXPERT SERVICE & INSTALLATION

Whether you are a year round business or a seasonal operation, we have a payment plan that will work for you. If you prefer a plan that provides budget assurance, we make paying for propane predictable and affordable.CYLINDER DELIVERY

Not only do we deliver propane cylinders to you, we also manage all propane-related equipment. We take care of servicing, safety, compliance and recertification of your cylinders and storage cages. You have a lot to worry about, and propane isn’t one of them.

Our Equipment Manufacturing Partners

We only work with equipment industry leaders, including:

CNGL Inc.

GE Power

Cavalier Industries Ltd.

Total Power

SECURE FUEL SUPPLY

We have extensive propane storage capacity in Canada and access to U.S. supply when needed. With access to an abundant supply and cross-border storage points, Superior Propane can reliably deliver to our customers. Superior proactively plans for seasonal demand by purchasing and storing increased inventory. We also offer:

LARGEST DISTRIBUTION FOOTPRINT

Superior has diverse transportation methods and contracts, and can mobilize quickly to increase inventory in preparation for changing demand. We have employed all channels including truck, rail, barge, pipeline and plane in order to get propane to our customers. We have the largest distribution footprint in Canada and are the only propane distributor in North America, with more than 170 storage and distribution points to serve almost 200,000 customer locations in more than 10,000 communities.EVENT PREPAREDNESS

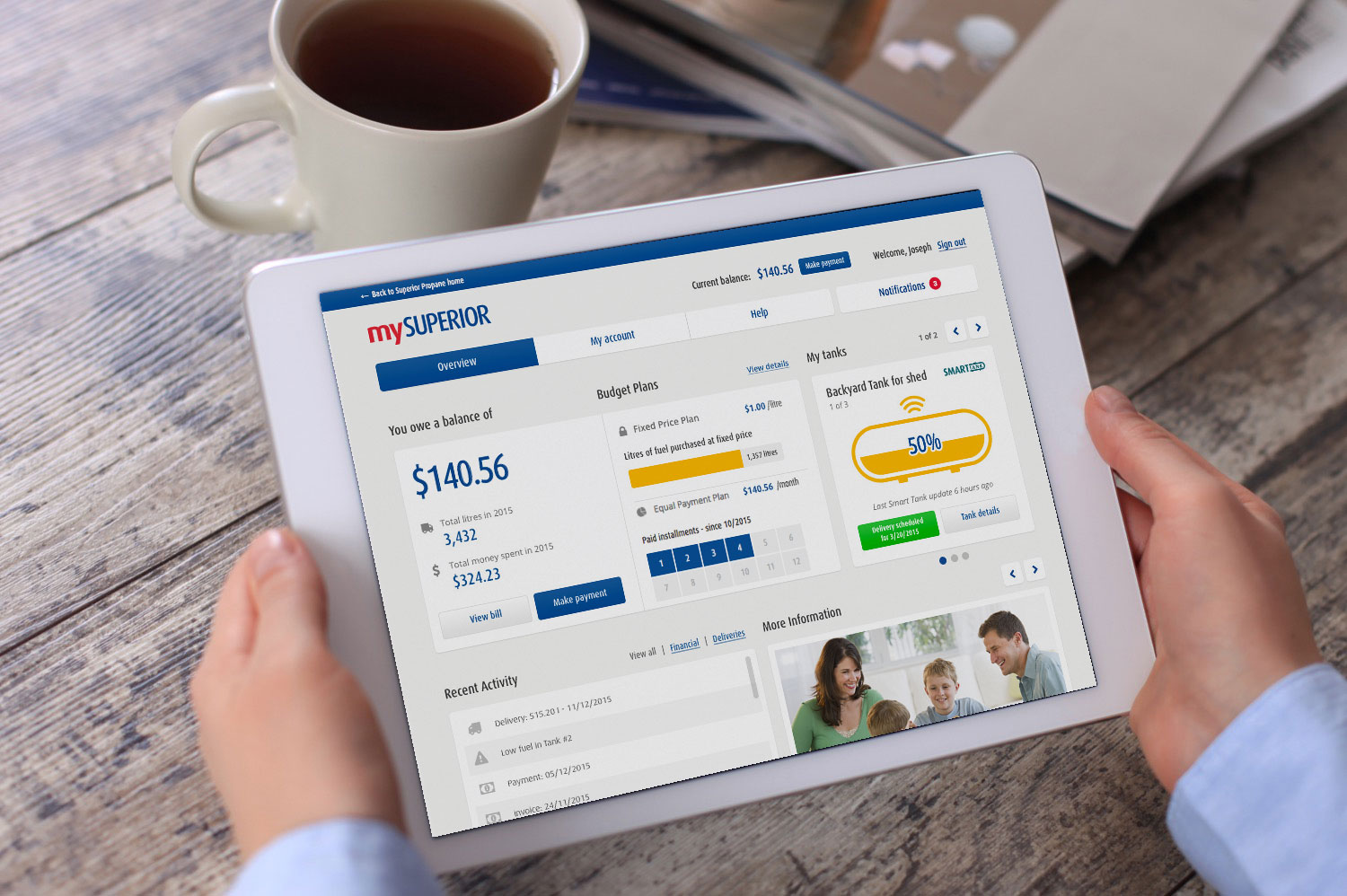

Whether it’s unforeseen weather or critical disruptions to transportation, our tank sensor technology allows us to remotely monitor tank levels and prioritize critical deliveries. Customers can also monitor their fuel levels through mySUPERIOR™️ online or our mobile app. Superior also maintains proactive customer communications and notifications as regular course as well as during critical events (ex. Supply Chain Disruptions 2014 due to Shale Gas Exports [wet crops, extreme cold winter] and the CN rail strike in 2019).

The Superior Difference

Propane Made Easy

Proven Expertise

Unmatched Reliability

SMART* Tank™ Wireless Monitoring

Reliable Propane Power and Heat Business Solutions

Propane Heat

Auto Propane

Power Generation

Contact Canada’s Leading Propane Supplier

OR

Call Us Now at

1-87SUPERIOR

1-877-873-7467